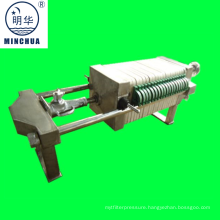

Leo Filter Press Sludge Filtration Filter Press,Automatic Operation Filter Press System for Sludge Dewatering

Product Description

Leo Filter Wastewater Treatment Plant Sludge Filter Press

Leo Filter Press is a professional Membrane Filter Press manufacturer,Leo filter press high pressure membrane filter press made by the high quality Membrane Filter Plate and the chamber arrangement of the composition filter chamber ,the conveying pump slurry under pressure to enter the filter chamber through the filter media (Filter Press Cloth) in the slurry to form filter cakes ,again through the membrane with air ,the filter press will full of solid ,the formed cake will have lower moisture content.When use membrane filter press for higher moisture content this machine have theri unique characteristics .

The membrane filter press is widely used in many different industries as when the slurry materials are sent to filter chamber by filter press feed pump. Then filtrating media( Filter Cloth ) separates solid and liquid in slurry material. When solid in slurry becomes cake shape, air is sent to membrane to squeeze to reduce moisture content. The membrane filter press can be used for, Reduction of the residual moisture of the filter cake,- Shorter filtration, wash and cake cycles;Drier filter cakes.

Filter Press Plate with enhanced molded polypropylene ,polypropylene plate with diaphragm mounted together ,sturdy ,secure ,easy off ,long service life .

1.Structure is made of high quality mild steel. It adopts automatic welding, solder side is flat, weld-joint is solid and durable, it can perfectly avoid distortion. It has reached the advanced technology in Europe and the United States.

2.Main-beam is processed by high speed centrifugal sand blasting to remove rust and iron oxide scale, then painted by epoxy micaceous iron primer to get better rustproof and corrosion resistance effect.

3.Filter press beams have stainless steel 304 covering to protect itself from wearing. The smooth surface of shell also make filter press plate shifting more easily and long service time during operation

4.Filter press plate is made from PP. It is tasteless and non-poisonous, safe with food and pharmacy industry. It is characterized by light weight, easy operation, acid and alkali resistance, high temperature and high pressure resistance.

5.Filter Press Hydraulic System adopts famous motor, it is steady in operation and easy in maintenance. Pistons are made of steel #45 after surface specially processed to get better anti-wearing and high hardness performance.

6.Electric control cabinet adopts renowned electrical components, it can realize auto closing, auto opening, auto pressure maintaining and trouble-free operation.

Product Categories : Special Industrial Filter Press > Sludge Filter Press

Premium Related Products