Automated Image Analysis of Particles

Product Description

Automated Image Analysis of Particles

Particle size distribution can greatly affect the efficiency of any collection device.

Settling chambers will normally only collect very large particles, those that can be separated using sieve trays.

Fabric filters are one of the most efficient and cost effective types of dust collectors available and can achieve a collection efficiency of more than 99% for very fine particles.

Wet scrubbers that use liquid are commonly known as wet scrubbers. In these systems, the scrubbing liquid (usually water) comes into contact with a gas stream containing dust particles. The greater the contact of the gas and liquid streams, the higher the dust removal efficiency.

Electrostatic precipitators use electrostatic forces to separate dust particles from exhaust gases. They can be very efficient at the collection of very fine particles.

Filter Press used for filtering liquids by cake filtration mechanism. Dynamic Foam Analyzer an important part in the cake formation, cake resistance, and cake characteristics.Automatic Foam Analyzers is determined largely by the size of the particles.

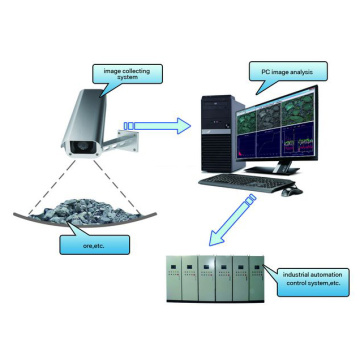

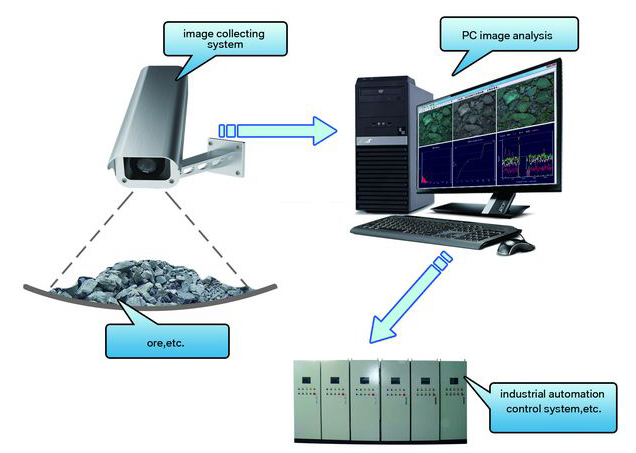

Product Principle

IA consists of image acquisition Automated Control Services system, image analysis system and data communication system. The image acquisition system complete video image acquisition by Foam Image Analyzer industry digital camera; the image analysis system captures Flotation Froth Image Analyzer image mainly through the image acquisition system, then comprehensively analyze through advanced algorithm and obtain the corresponding flotation foam characteristic parameters, finally through the data communication system by using OPC/Modbus mode for data transmission to industry automatic control system, thus for optimize control, expert system control, etc.

Product Characteristic

Using professional HD computer vision industrial camera, image display is clearer and color looks more real so that it can provide first-line flotation personnel with real-time froth video images;

■ Advanced industrial vision technology, advanced vision analysis algorithm and accurate froth division result;

■ Electric separation and convenient control and maintenance;

■ With high cost performance, system and equipment don’t cost too much; It’s easy to install due to small floor space;

■ Based on statistical theory, it’s more scientific and reliable than manual observation;

■ Transmission via kilomega network (GigE) leads to stable image data signal;

■ Image high frequency measurement, analyzing time of single point less than 200ms, improve measurement accuracy;

■ Through hardware extension, observation point extends infinitely.

■ To support such common industrial communication protocols as OPC/MODBUS, etc. It is easily integrated into industrial control system;

■ It can equip with real-time data base, provide images and analysis data storage function, which makes it convenient to query, count up, analyze and trace back the historical data during flotation production process.

Product Parameter

1) Parameter information

■ Froth size and quantity

■ Percentage of froth in different size

■ RGB and HSV model for froth color

■ Average froth movement speed

■ Life cycle of froth (percentage of damage)

■ Froth texture status

2) Technical Index

■ Detection mode: Non-contact detection

■ Detection content: The real-time variation of froth during ore-dressing flotation production process

■ Recognition speed: Single point analysis time is less than 200ms

■ Communication mode: OPC/MODBUS TCP etc

Product Application

■ To provide real-time froth video image with the first-line flotation personnel

■ To provide data support for normative flotation control

■ To provide data support for production traceability of flotation

■ To provide data support for flotation optimal control

■ To provide data support for flotation expert system control

■ To monitor froth movement speed on the overflow along

Product Categories : Image Analyzer